We usually use rotary vane pump is not always normal operation, occasionally will face failure, this situation is generally due to improper operation, we must first judge where the fault, ready to repair the program. If the working condition is corrosive and toxic and harmful, it should be cleaned before maintenance to prevent damage to maintenance personnel.

Before understanding the maintenance method of rotary vane pump, first understand what are the common faults of bipolar rotary vane pump. Common faults are: oil leakage, oil injection, water leakage, smoke, noise, pump does not turn, pump temperature is too high, high power, limit pressure is not up to the standard and so on. The following three kinds of fault maintenance methods to share with you.

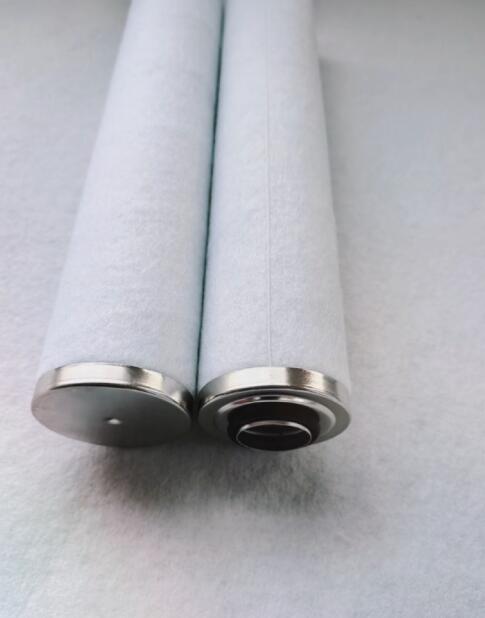

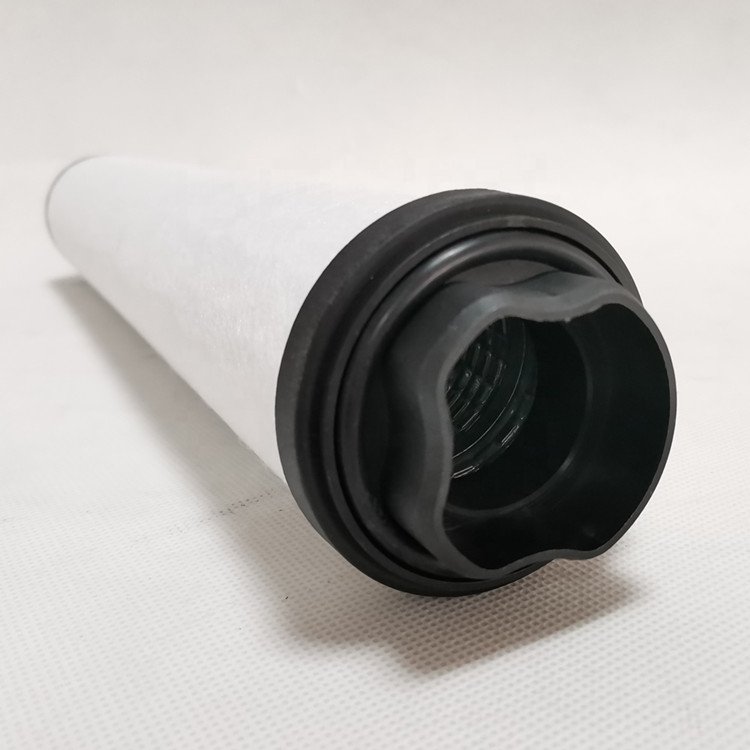

Oil LEAKAGE: Oil leakage can occur in many parts of the pump, because it can occur at any sealed joint. It is very common in oil seal vacuum pumps and is difficult to prevent. After oil leakage is found, the pump must be stopped, the gas valve must be closed, the oil leakage place must be found and the corresponding oil leakage device must be replaced. For example, such as the pump filter and pump connection port sealing is not good enough will occur oil leakage, this time need to replace a relatively good sealing filter, filter brother filter sealing is professional detection, are in line with the standard.

Large noise: if the rotary vane pump noise suddenly become bigger, more than the usual operation noise, showed that there was a problem in vacuum pump, it is possible that parts damaged motor bearings or likely also itself there is a problem, cause the noise of the parts are: seal, o-ring, rotate the three blades, maintenance good pump after also need to adhere to the time for maintenance and cleaning, prevent damage of again in a short period of time.

The pump does not turn: this time must first turn off the pump power, stop operation, do not know the reason for blind start the pump is easy to cause other failures, the loss outweighed the gain. After finding that the pump does not turn, the pump body should be opened first and the rotor should be moved by hand disk. If the disk does not move the rotor, it may be that the viscosity of the pump oil is too high, foreign bodies are stuck in the pump or the starting temperature is too low. If it can work, the reasons may appear in the coupling failure, motor damage, wiring error or power supply, etc.

Contact: Sunny

Phone: +86-18790023620

Tel: 18790023620

Email: info@jyzyfilter.com

Add: Building 2,NO.218,Convenience Service Center,Silangyao Village,DayuTown,Jiyuan ,Henan,China

We chat